SAP and Oracle are two different vendors and have a clear market share with established product lines. Oracle is a famous technology service provider, most commonly for DBMS, and SAP is well-known for Enterprise Resource Planning (ERP) and professionals who are trained in these systems understand the business activities like Production Planning, Material Management, Finance and Controlling and others. Aspirants need to undergo SAP program to get in-depth knowledge about the product.

Before checking out the difference, let us explain about these two technologies:

SAP: Systems, Applications and Products in Data Processing helps in integrating different business applications. The product allows real time tracking of business activities rather than using different products for different activities. SAP ERP is highly recommended by IT companies to make the business activities easy and faster. Moreover, it fits to both small and large IT companies.

ORACLE: Produced by Oracle Corporation, the software is used in large enterprise environments. In Oracle DBMS, data is completely accessed using SQL (Structured Query Language), the commands of which can be embedded in different languages. The product uses two levels:

- First Level: Logical storage organized as tablespace

- Second Level: Physical Storage completely made up of data files.

Difference between SAP and Oracle:

SAP ERP Training is complex software and used in both large and small companies to integrate business activities, while Oracle is ORDBMS, used only large enterprise companies. One needs to have complete SAP education to use its complexity. Moreover, it is developed to be used in various database systems, including the interfaces for Oracle cloud training.

Implementation and Cost:

When comparing the implementation cost of both, SAP Corporate training is considered as higher cost option. In an average, a company spends 4% of its annual value, compared to Oracle which needs 1.7% in implementation.

Functionality and Customization:

Every product should be designed for easy functionality and customization. In case of SAP and Oracle, customers are customizing the product according to the requirement. Oracle offers solutions for project teams aren’t in need of customizing the software, while SAP S4/HANA Finance Training users customize and integrate the tool making it more flexible to use.

Once you have a clear picture about the difference between SAP and Oracle, you can check the SAP program and Oracle online training, which are structured according to the skills to streamline the business process in cost effective.

Under SAP ABAP training program, aspirants will be given training on Oracle Cloud for Customer (C4C), Finance and Controlling, Material Management, HR and others. Similarly in Oracle, aspirants will hone the skills of Installing and Configuring Oracle, Managing Oracle Instance using Enterprise Manager, Utilize Oracle Managed Files and others.

Now, software tester can enroll in software testing courses to get in-depth knowledge, to employ high-end automated test execution tools for entering same test data multiple times.

Now, software tester can enroll in software testing courses to get in-depth knowledge, to employ high-end automated test execution tools for entering same test data multiple times.

How and where Microsoft Dynamics AX Financial can be used?

Microsoft Dynamics AX Financial is

How and where Microsoft Dynamics AX Financial can be used?

Microsoft Dynamics AX Financial is

SAP system is too large for one person to know everything, as it is a large and complex system so the SAP consultants work through a dedicated profile to help them achieve their organizational goals. The SAP technological work process incorporates different services that allow companies to manage their business more efficiently. The only requirement to become a consultant is to enroll in SAP certification course from a certified training center.

Technical Grade SAP Modules

The professionals with excellent written and verbal communication and presentation skills can seek SAP online course, to facilitate programming knowledge of ABAP and BASIS. Strong skills in all technical areas along with good problem solving and analytical skills in areas of Netweaver - Workflow, BAPI, Reports, BDCs, RFCs, BADI, Data Dictionary, ALE/EDI/IDOC, and SAP scripts, is a must for ABAP consultant.

As people with SAP skills are the highest paid in the industry, so there is a consistent requirement of the right person with the right experience. The multinational companies seek professionals with a rich experience in SAP domain and publish job vacancies in various job portals, to hire the suitable candidate for SAP profile. There are plenty of employment opportunities for persons with SAP skills, as most trained consultants only work with one or two modules.

Functional Grade SAP Modules

SAP system is too large for one person to know everything, as it is a large and complex system so the SAP consultants work through a dedicated profile to help them achieve their organizational goals. The SAP technological work process incorporates different services that allow companies to manage their business more efficiently. The only requirement to become a consultant is to enroll in SAP certification course from a certified training center.

Technical Grade SAP Modules

The professionals with excellent written and verbal communication and presentation skills can seek SAP online course, to facilitate programming knowledge of ABAP and BASIS. Strong skills in all technical areas along with good problem solving and analytical skills in areas of Netweaver - Workflow, BAPI, Reports, BDCs, RFCs, BADI, Data Dictionary, ALE/EDI/IDOC, and SAP scripts, is a must for ABAP consultant.

As people with SAP skills are the highest paid in the industry, so there is a consistent requirement of the right person with the right experience. The multinational companies seek professionals with a rich experience in SAP domain and publish job vacancies in various job portals, to hire the suitable candidate for SAP profile. There are plenty of employment opportunities for persons with SAP skills, as most trained consultants only work with one or two modules.

Functional Grade SAP Modules

CCNA R&S is the entry level breakthrough certification by Cisco that proves capability & expertise in medium-size routed and switched networks. The Network Specialist is responsible to diagnose, troubleshoot, debug and resolve networking issues. As a network engineer this profile requires setting up networks that encompass on network solutions for all the systems that are online all the time.

By getting enrolled in the course and enhancing the expertise, along with Cisco certification, you can get a great head-start in your career with a big organization, demonstrating your skills and knowledge in this field to grab higher salary and better career growth. Some of the key specific areas of expertise include:

CCNA R&S is the entry level breakthrough certification by Cisco that proves capability & expertise in medium-size routed and switched networks. The Network Specialist is responsible to diagnose, troubleshoot, debug and resolve networking issues. As a network engineer this profile requires setting up networks that encompass on network solutions for all the systems that are online all the time.

By getting enrolled in the course and enhancing the expertise, along with Cisco certification, you can get a great head-start in your career with a big organization, demonstrating your skills and knowledge in this field to grab higher salary and better career growth. Some of the key specific areas of expertise include:

ITIL certification can be used by organization to train with special technique. Aspirants taking up the ITIL course can look forward to five different levels:

ITIL certification can be used by organization to train with special technique. Aspirants taking up the ITIL course can look forward to five different levels:

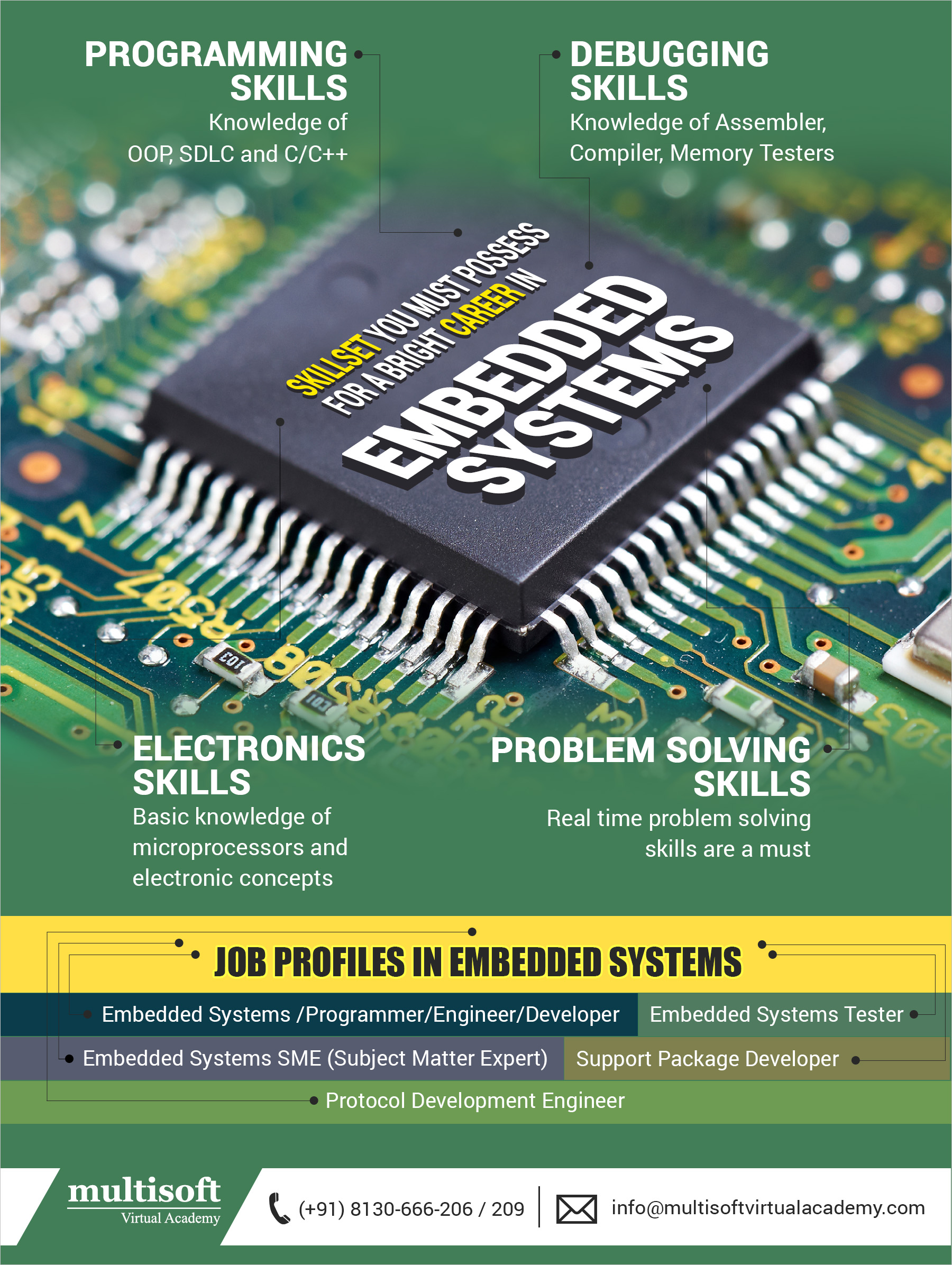

Questions and Answers based on Embedded Systems

Q1. Explain embedded system?

Ans1. An embedded system uses the power of hardware and software. Based on program present on the embedded system chip, the embedded system performs specific functions.

Q2. What are different types of embedded system?

Ans2. Different types of embedded system are:

Questions and Answers based on Embedded Systems

Q1. Explain embedded system?

Ans1. An embedded system uses the power of hardware and software. Based on program present on the embedded system chip, the embedded system performs specific functions.

Q2. What are different types of embedded system?

Ans2. Different types of embedded system are:

As evident, the knowledge of CAD/CAM puts you into a wider realm of opportunity when you are looking to earn a career in designing. To facilitate the same, there are a variety of CAD courses available online that makes you ready for the industry. CAD/CAM is an interesting area of work and apart from letting you do what you are passionate about, the job also pays well and promises plenty of growth.

The basic role for any CAD/CAM programmer/designer involves:

As evident, the knowledge of CAD/CAM puts you into a wider realm of opportunity when you are looking to earn a career in designing. To facilitate the same, there are a variety of CAD courses available online that makes you ready for the industry. CAD/CAM is an interesting area of work and apart from letting you do what you are passionate about, the job also pays well and promises plenty of growth.

The basic role for any CAD/CAM programmer/designer involves:

According to IBM report on customer migration from open source to WebSphere, the businesses have gained high ROI and profit with this technology. However, one needs to have basic and in-depth knowledge of this tool by undergoing

According to IBM report on customer migration from open source to WebSphere, the businesses have gained high ROI and profit with this technology. However, one needs to have basic and in-depth knowledge of this tool by undergoing

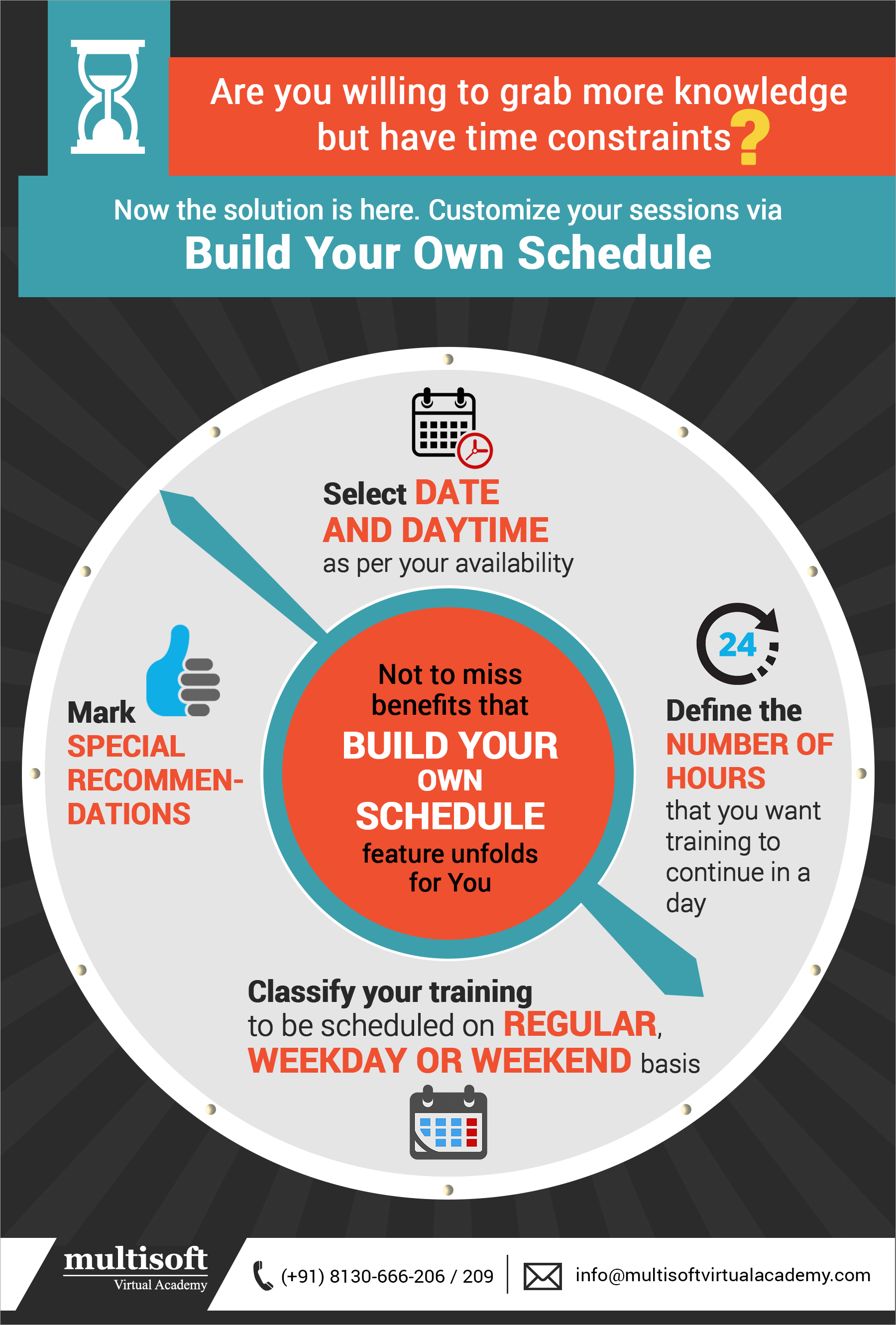

Join our Live Instructor-Led online classes delivered by industry experts

Join our Live Instructor-Led online classes delivered by industry experts